What Is DTF Printing?

How Does DTF Printing Work?

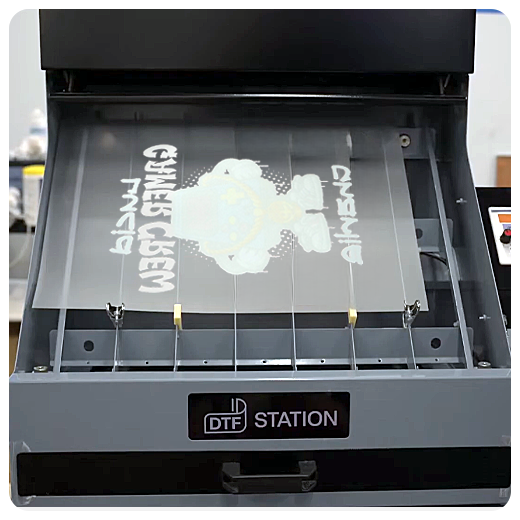

1. Print

Print your design on transfer film using special high-quality, color-rich inks.

2. Powder

After printing, apply a backing powder to the film by hand or use an automatic powder shaker. This backing powder will bond your transfer to any color garment.

3. Cure

Cure (melt) the powder on your transfer film to prepare it for application. We recommend a curing oven, but you can also use a heat press.

4. Press

Once the design is cured, it is ready to be applied to garments, hats, bags, and more using a heat press.

The Benefits Of DTF Printing

-

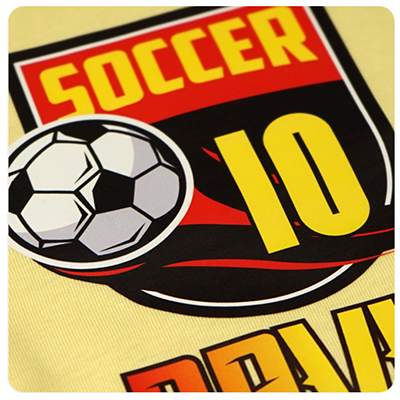

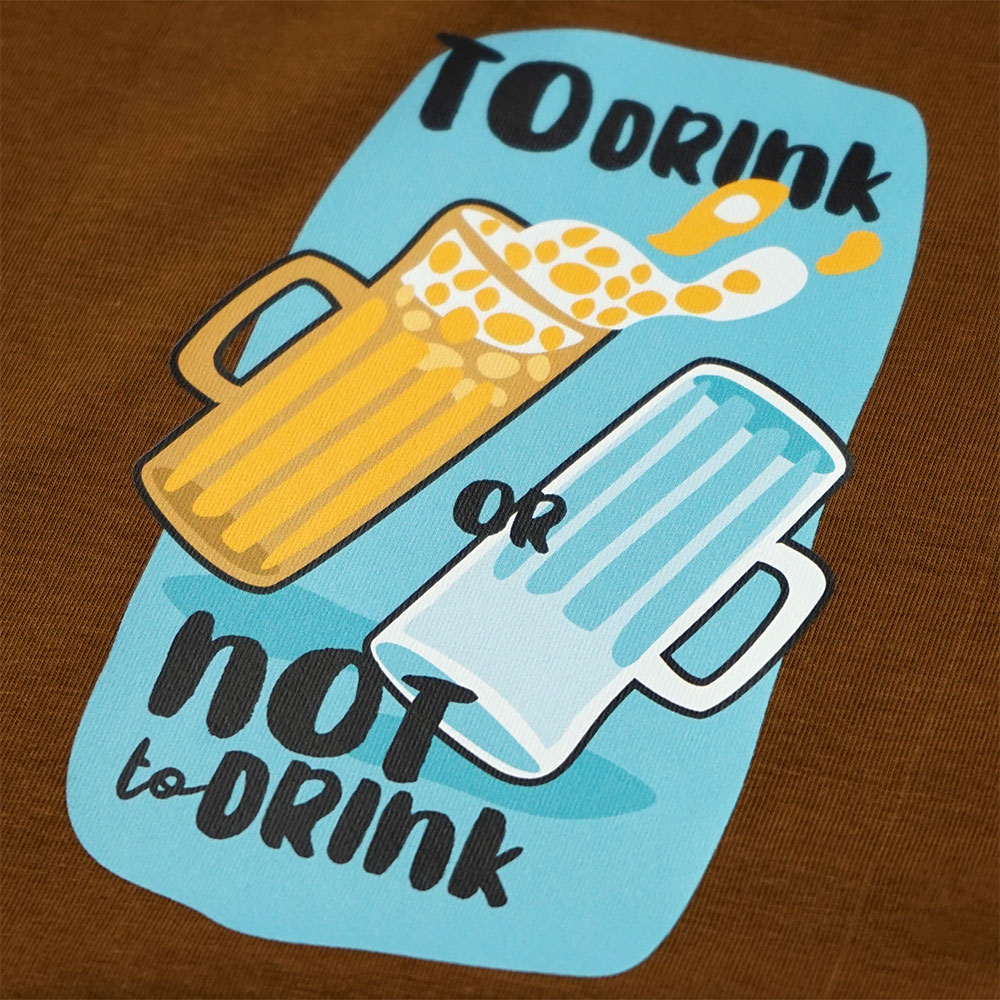

Full Rich Color

CMYK backed with white ink makes the colors pop.

-

Super Sharp Detail

With very high DPI you get sharp edges without color bleed.

-

Easy To Use

Detailed video instructions get you up and running fast.

-

Washability

Designs look just like new after 50+ washes.

-

No Minimum Production

Print and sell as little as one design.

-

High Stretchability

Designs stretch without cracking or peeling.

-

Test New Designs

Go from inspiration to finished product within hours.

-

Easy Application

Lower temperature setting than most transfers to adhere in seconds.

You'll Get Amazing Results

What You'll Need For DTF Printing

Starter Package Recommendations

Financing Available

Financing Available

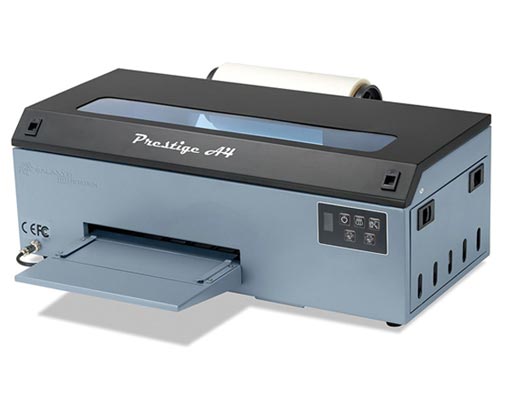

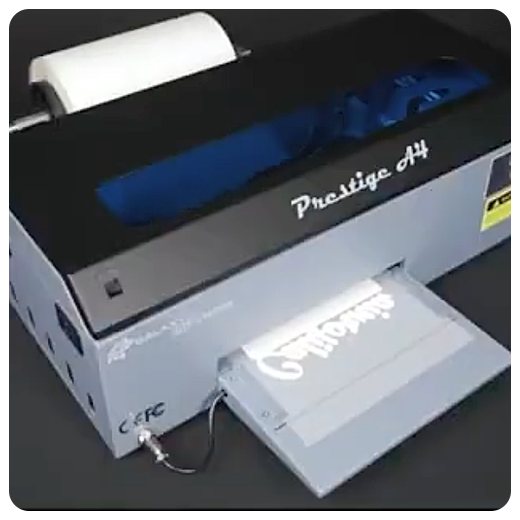

- Prestige A4 DTF Printer

- Phoenix Air 16x20 Curing Oven

- DTF Station Hot Melt Powder

- DTF Film Sheets

- Color Max Inks

- Cleaning Solution & Supplies

Financing Available

Financing Available

- Prestige R2 DTF Printer

- Seismo 11 Powder Applicator/Dryer

- Purifier MINI

- DTF Station Hot Melt Powder

- DTF Station Film

- Color Max Inks

- Cleaning Solution & Supplies

Financing Available

Financing Available

- Prestige R2 DTF Printer

- Seismo M16 Powder Applicator/Dryer

- Phoenix Air 16x20 Curing Oven

- Purifier L2 Portable Air Purifier

- DTF Station Hot Melt Powder

- DTF Station Film

- Color Max Inks

- Cleaning Solution & Supplies

Questions? Talk To An Expert.

FAQ

-

How does a DTF Printer work?

DTF Printers function by printing CMYK colors and then applying white ink to a specially coated film. In contrast to direct-to-garment (DTG) printing, DTF uses a "reverse order" approach, beginning with color printing and concluding with the application of white ink.

-

What maintenance do DTF Printers need?

DTF printers require regular maintenance, primarily centered around the upkeep of the print heads. Ensuring the print heads optimal condition is vital for consistent and high-quality printing performance. Regular maintenance activities involve cleaning, nozzle checks, and possibly occasional replacements to guarantee the smooth flow of ink and accurate image rendering.

-

Do you provide training?

Yes, all DTF printers include a training session with the manufacturer to ensure setup and installation is accurate for the best possible experience with your new equipment.

-

Do I need special software for DTF printing?

Yes, DTF printers require specific rip software or specialized software to function effectively. The range and sophistication of available software options vary, spanning from simpler versions to those that offer comprehensive control. Gaining precise control over elements like color profiling and the size of picoliter (ink drop) plays a pivotal role in achieving top-notch quality in DTF prints.

-

What computer is needed for the RIP software?

The RIP software can be used with a PC. It is not compatible with MAC.

-

Is a DTF powder station necessary?

No, a DTF powder applicator isn't essential for all DTF printing. It's typically used in the production of DTF printing (roll setups), not for individual sheet printing. You can manually apply the powder to the printed sheet.

-

What type of ink does DTF use?

DTF uses pigment-based ink for a 4-color process (Cyan, Magenta, Yellow, Black), with white ink printed last.

-

What type of film is used in DTF?

DTF uses specially coated PET films that accept and release ink when heated and pressed onto fabric.

-

Is DTF limited to specific shirt materials?

DTF works on various fabrics including cotton, 50/50, polyester and tri-blends.

-

How soon after printing does the powder need to be applied?

We recommend the powder be applied within 2 hours of printing before the white ink dries.Best practice is to apply the powder immediately after printing.

-

When should I cure the film after the powder has been applied?

We recommend curing the film as soon as you apply the powder for the best results.

-

Do I have to use a DTF transfer right away?

No, they can be stored and used for up to a year.

-

What is DTF Powder and do I need it?

DTF powder is necessary for transfers to adhere; it's granular and comes in different types. regular, medium and course. Finer powder often results in a softer “hand” (feel) of the transfer after pressing.

-

When should I use black DTF powder?

Black DTF powder should be used to avoid dye migration when printing on a dark garments. This will help reduce visible powder residue. Using black powder could darken the overall appearance of the design once printed.

-

How do I apply DTF Powder?

Powder can be applied manually by pouring the powder over a wet transfer and shaking off the excess. Or, you can use a powder applicator to speed up production. Some powder applicators include an oven to cure the transfer once the powder has been applied, which would reduce the amount of equipment needed.

-

How do I melt DTF Powder?

There are various methods to melt the powder. The most frequently used, and budget-friendly, approach is by using a heat press and hovering the heating element over the transfer. Alternatively, you can use a curing oven which would speed up production and free up your heat press.

-

Do I need to pre-treat with DTF?

No pre-treatment is required for DTF.

-

What's the cost for printing an A3 sheet?

Approximately $.80-1.08 per print which includes the ink, film and powder. This calculation is an estimate and the actual cost may vary depending on the image size/type, brand of DTF film/sheet, and the amount of powder used.

-

How long will a DTF transfer last on a garment?

We estimate about 50+ washes before you experience fading within the design. Washing the garment inside out can prolong the life of the design.

-

How's DTF washability?

DTF transfers can withstand washing at 40°C with proper application and quality powder.

-

How does DTF feel?

The texture would vary based on the powder type and ink layer thickness. A greater amount of ink will absorb more powder, resulting in a thicker sensation overall. Our soft and stretchy DTF powder provides a superior feel compared to conventional vinyl or other heat transfer methods. It has an elastic, gentle touch that's pleasant. It's worth noting that it's not softer than DTG prints, though.

-

What happens when the printer is not used for an extended period of time?

Like other printers, DTF printers can clog if left inactive; flushing and cleaning are recommended. If leaving your DTF printer inactive for a long period of time, you should follow procedures for a ‘long store’ to ensure the printer is prepped properly.

-

What is the preferred format for printing a design?

We recommend using a png file with a transparent background.

-

How can you tell if the ink has expired or should not be used?

The ink should not be used past the expiration date that is listed on the container. If the ink appears translucent in the lines, instead of the actual color, the ink should be flushed and replaced. We recommend shaking the extra bottle of white ink (the ink not in the printer) every 2 days, to ensure the ink is kept moving and is ready to use.

-

Where should I store the printer and supplies?

The printer and supplies should be kept in a climate controlled environment.

-

Do I need protective wear when working with the products?

It is best practice to use gloves, eye protection and a mask when working with the powder and curing the transfer. A well ventilated area and /or air filter are recommended.

-

How many transfers can 1kg of hot melt powder cover?

1 kg can coat about 200 transfers.

-

Other consumable ratios; based on a roll of 24” media (24” x 325 ft)

- • 1 roll : 2L white ink

- • 1 roll: 1.6 bags of powder

- • 6 L white = 1 of CMYK